HOME

Benithem Sdn. Bhd. – Pekan Nanas, Johor

July - October 2022 (12 weeks)

During my industrial training at Benithem Sdn. Bhd., an ergonomic furniture manufacturer, I was placed in the Research & Development (R&D) Department. My time there gave me valuable hands-on experience in product design, CNC programming, and understanding the workflow between design and production teams.

Key Responsibilities:

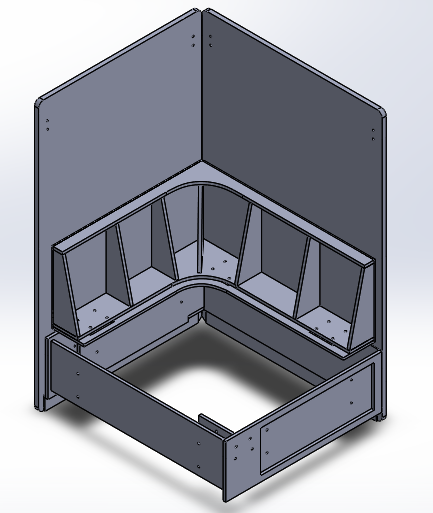

• Designed and modified 3D furniture models using SolidWorks for various product lines including BANQ Series, ROOF POD, MODE, and SOFA 708

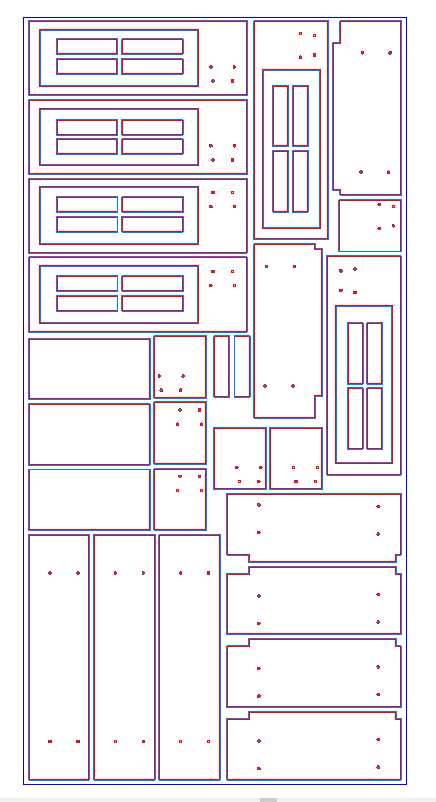

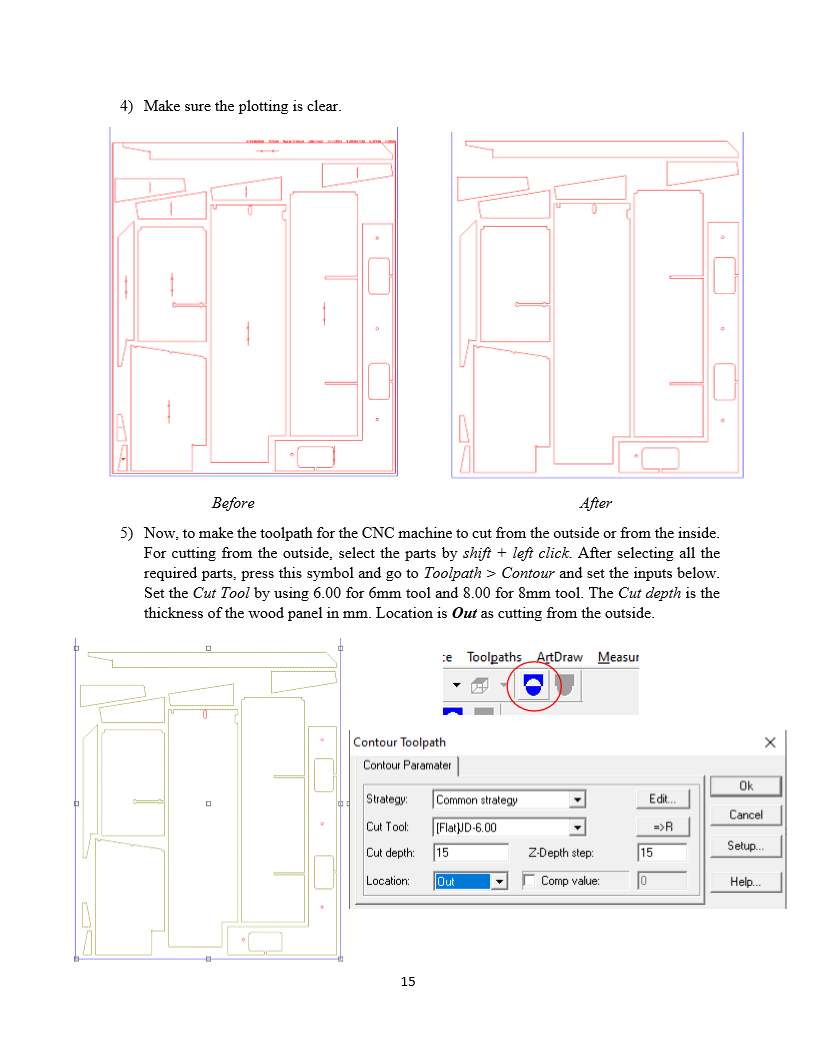

• Created CNC files (.nc) for plywood cutting and product prototyping using various softwares

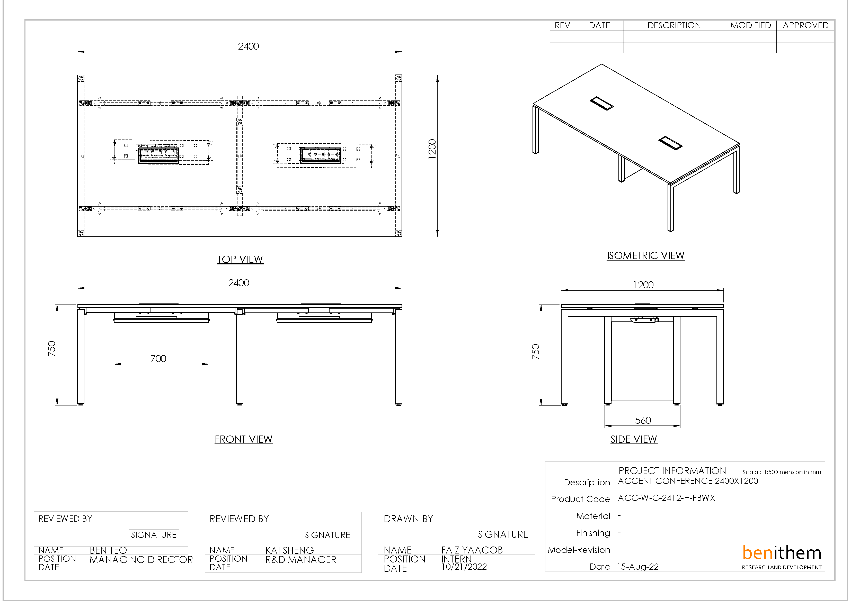

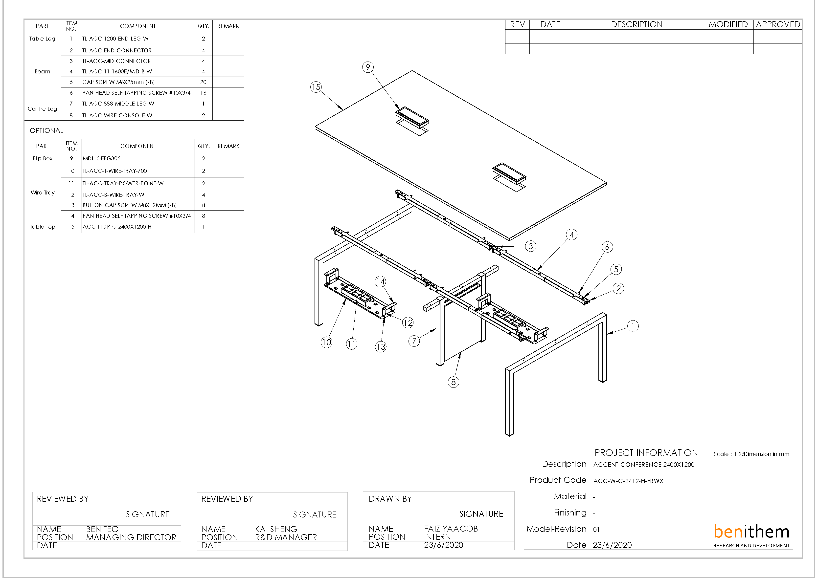

• Prepared technical drawings and Bills of Materials (BOM) for production and marketing; updated over 67 legacy drawings to align with current file standards

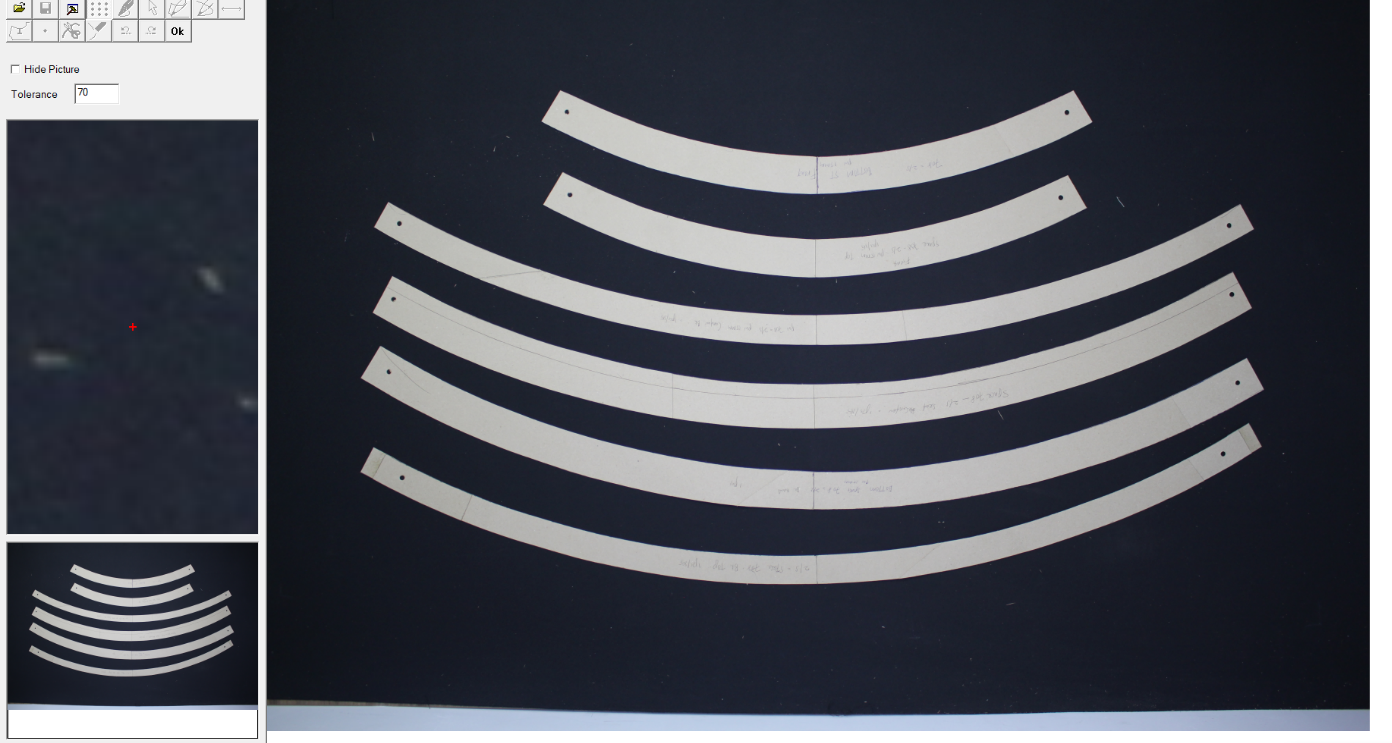

• Developed comprehensive user guides and documentation including "Instructions on How to Convert from SolidWorks Parts to CNC Files" (19 pages), "Instructions on How to Make a Mould File Using Camera" (12 pages), and "Instructions on How to Print DGS File" (6 pages)

• Assisted engineers and designers in troubleshooting design and fitting issues, including solving alignment problems for BANQ spanning screens

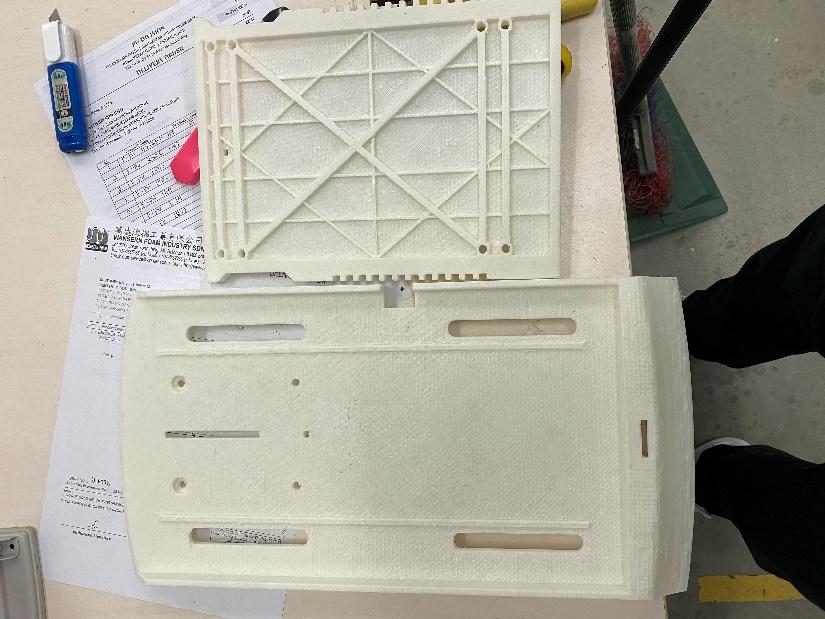

• Operated 3D printers for prototype fabrication and learned maintenance procedures including base tape replacement and excess print removal

• Supported product development across multiple furniture lines: BANQ Series (2-seater and 3-seater variants, corner configurations, panel modifications), ROOF POD (Single Pod, Double Pod, Meeting Pod with glass variants), customized tables for ACCENT and MODUL series with various configurations (Conference, Manager, Workstation), and custom orders like SOFA 708 2-seater and 3-seater expansions

BENITHEM

ABOUT ME:

Born on 9 October 2000 in Skudai, Johor. Graduated in Mechanical Engineering - Industry from Universiti Teknologi Malaysia.

Currently seeking experience in engineering roles and are looking forward on automation and AI integration for industrial use.

INSTRUMENTATION

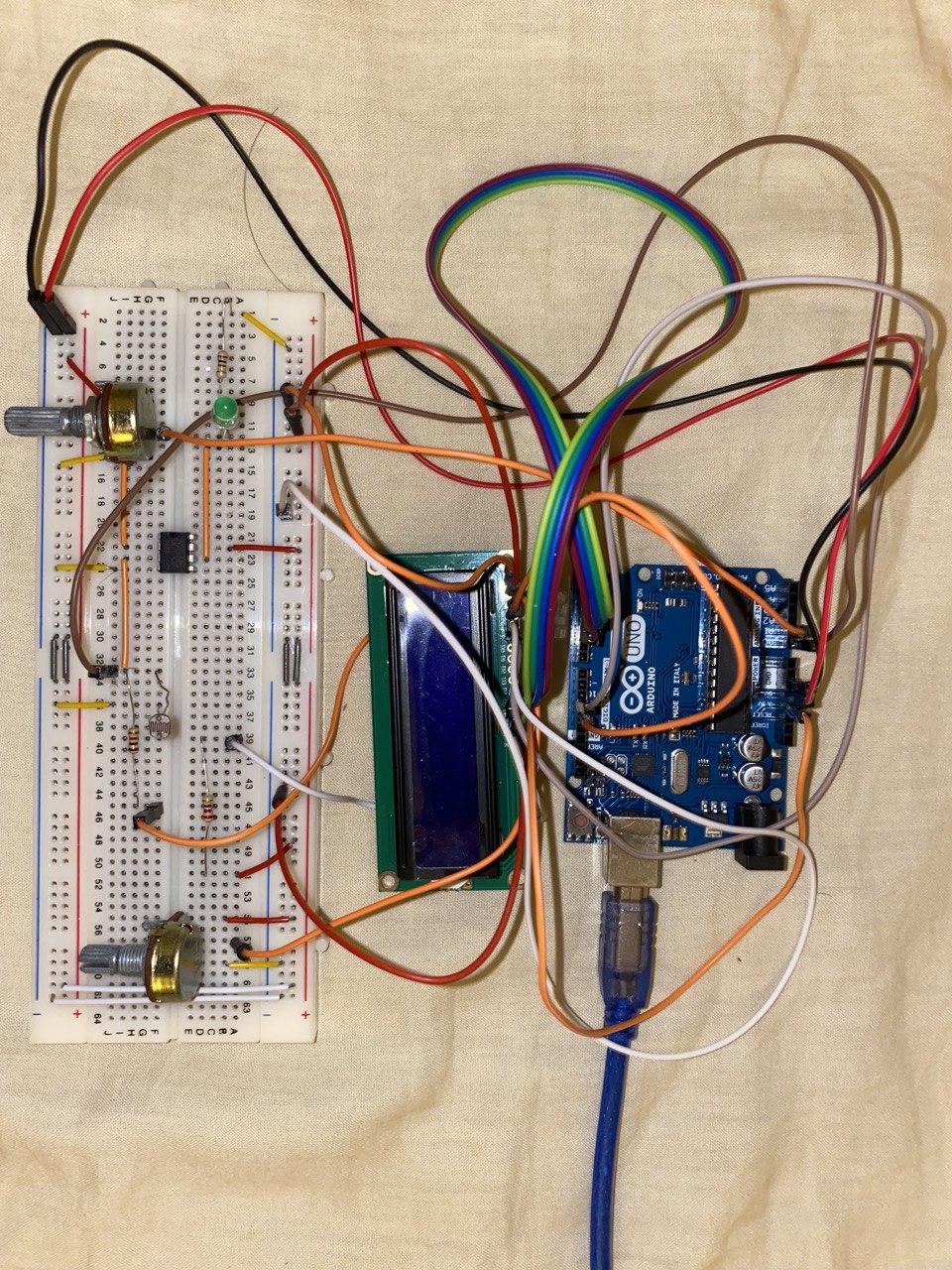

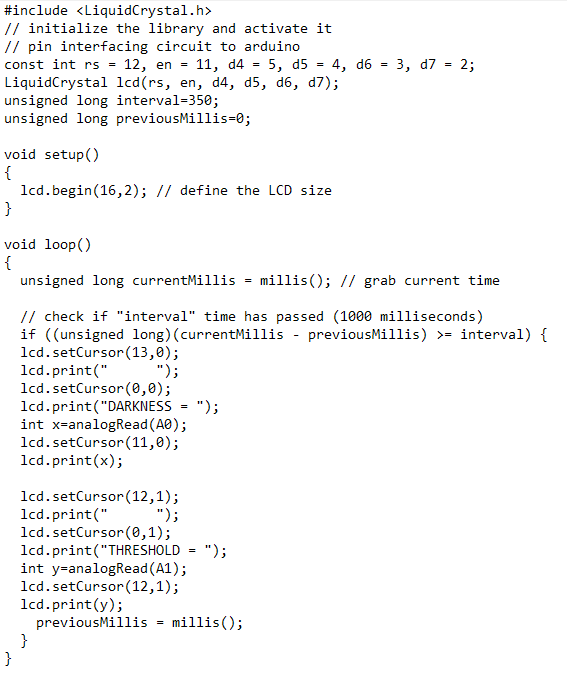

Objective : Design and calibrate an instrumentation system that measures light intensity using a Light Dependent Resistor (LDR) sensor with adjustable sensitivity and automatic LED response based on ambient light levels.

In this project, I first designed and simulated the dark sensor circuit in TinkerCAD before assembling it on a breadboard. The system uses an LDR sensor paired with an Op-Amp comparator circuit for precise threshold detection, integrated with Arduino for data processing and real-time display on an LCD screen. The system was calibrated and tested under different lighting conditions to ensure the threshold responded accurately and consistently. This project demonstrates practical IoT applications including smart street lighting and security monitoring systems.

Tools Used: TinkerCAD, Arduino Uno R3, Op-Amp 741, LDR sensor, LCD 16x2 display, breadboard

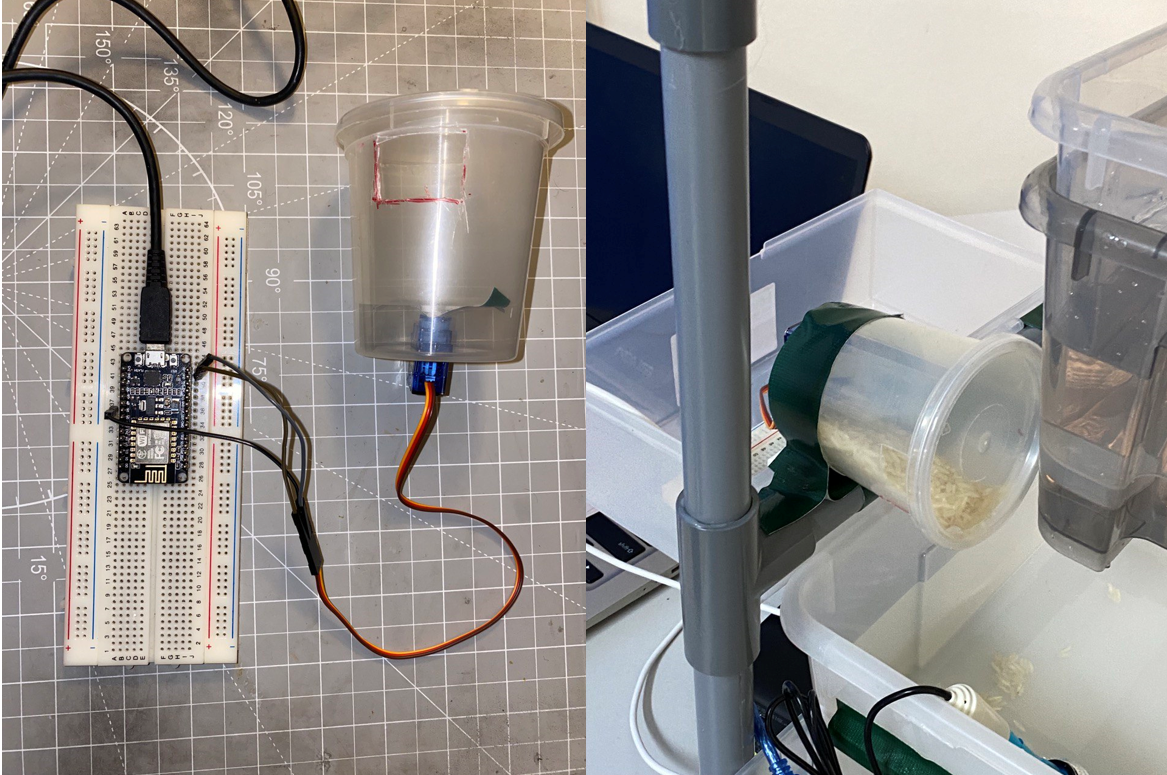

SMART LOBSTER FARM

Objective: Design an automated and sustainable lobster breeding system integrating IoT and aquaponics principles to improve water quality, feeding efficiency, and system monitoring.

This project focused on developing a smart aquaponic lobster farming system that integrates IoT automation with sustainable aquaculture design. My main contributions involved creating the concept sketches for the three-tier recirculating tank system layout and developing the IoT-based feeding mechanism. The feeding system was self-built using a servo motor and modified plastic cups, programmed through an ESP8266 microcontroller and controlled remotely via the Blynk IoT platform. The final prototype successfully demonstrated automated feeding, efficient water circulation through aquaponics, and a practical approach to smart aquaculture.

Tools Used: Arduino Uno R3, SolidWorks, Blynk IoT Platform, ESP8266 Microcontroller, pH Sensor Kit, Breadboard Prototyping

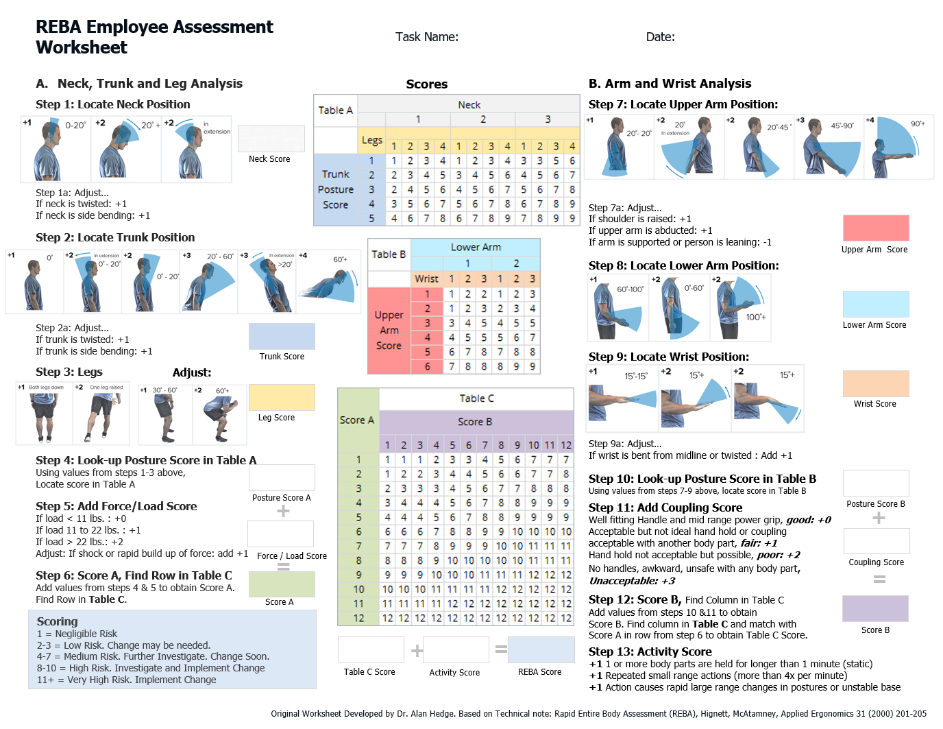

FINAL YEAR PROJECT

Objective: Design an ergonomic solution to reduce musculoskeletal strain during the refilling process of vending machines by developing a lifting-assist trolley system.

This project aimed to improve the ergonomics of refilling tasks in a vending machine business. Through ergonomic risk assessments (REBA, MAC, and EMG), key issues such as awkward postures and excessive lifting effort were identified. Based on these findings, I designed a mechanical trolley system in SolidWorks to help workers transport and lift drink containers more efficiently. The design incorporated a gravity-feed mechanism and adjustable height system to simplify loading while minimizing strain. Testing and analysis showed that the new trolley eliminated high-risk postures and reduced manual effort by 62%, enhancing both worker safety and operational efficiency.

Tools Used: SolidWorks, Arduino Uno R3, EMG Sensor, Excel Data Streamer

ACADEMIC

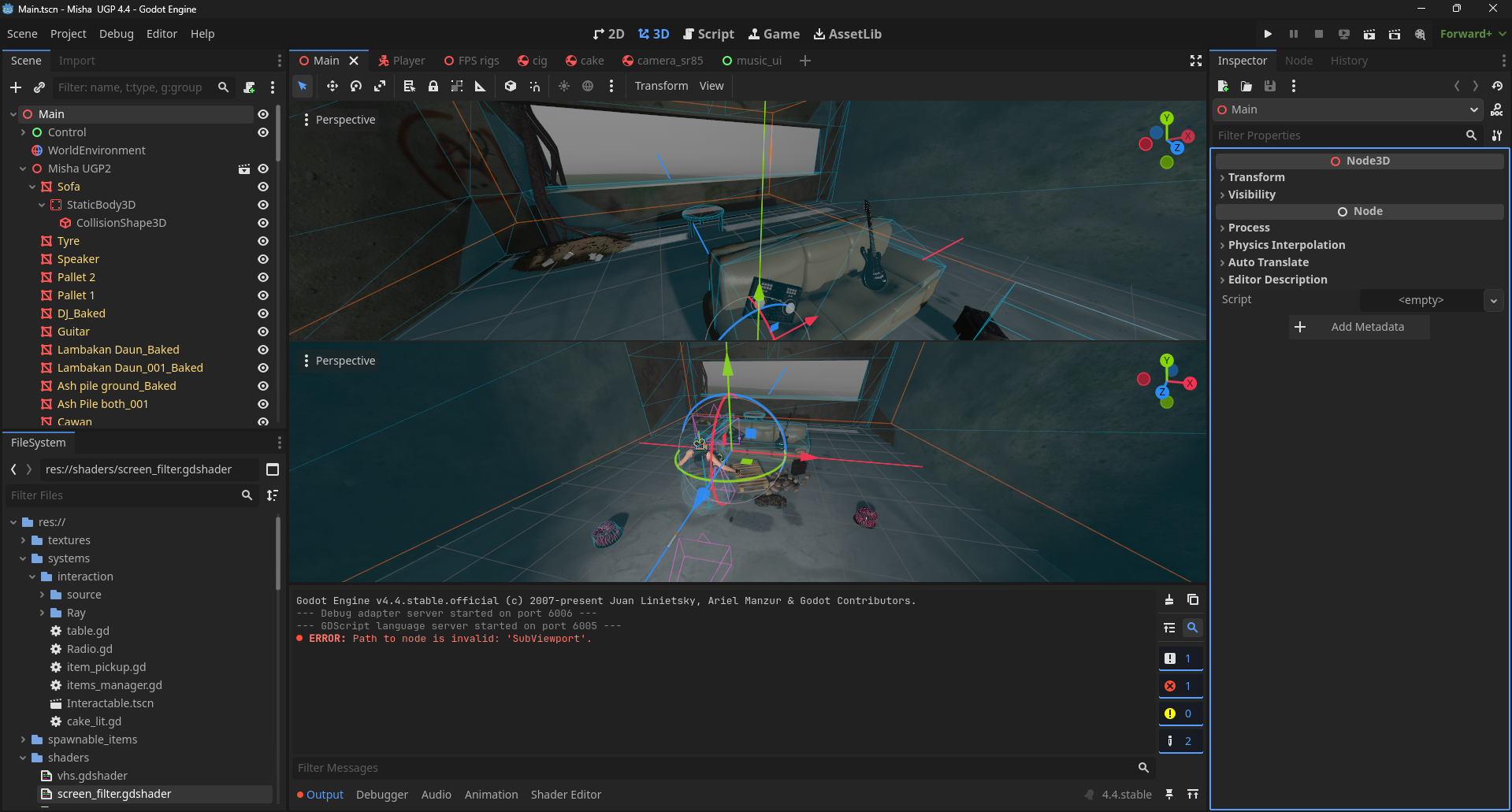

Godot - a free, open-source game engine for developing 2D and 3D games across various platforms like PC, mobile, and web

After learning the basics of 3D modeling, I decided to explore game development. While searching for a subject to focus on, I eventually chose underground artist Killamisha and her album Underground Princess as my inspiration and design reference.

I used the album cover’s background as the basis for the environment. I started by modeling the layout and then created each individual item, using reference images from the internet. After completing the models, I applied textures—some were created procedurally, while others were sourced externally. Once the environment closely resembled the original reference, I began learning GDScript to implement functionality in Godot.

Demo video.

GODOT

Blender - a free and open-source 3D creation software

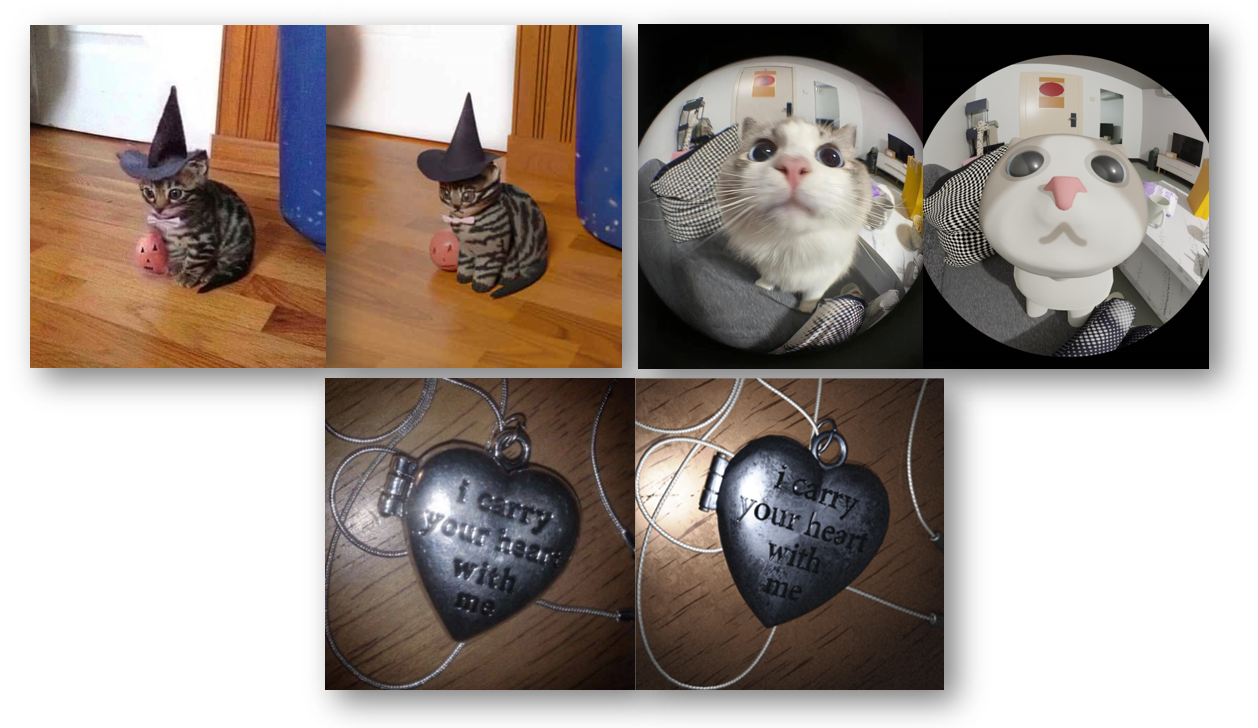

I began learning 3D modelling through SolidWorks during my studies, and later expanded my skillset to Blender to explore mesh-based workflows and artistic modelling. Blender's approach differs significantly from parametric CAD software, requiring a different methodology for creating and manipulating 3D forms.

I developed my skills by modelling everyday objects, which helped me understand mesh topology, edge flow, and polygon modelling techniques. This practice included learning texture creation through both procedural methods and texture painting, as well as UV mapping to ensure consistent texture quality across surfaces. Through this process, I gained proficiency in the complete 3D asset pipeline, from initial modelling and texturing to final rendering and export.

Simple models compiled during my Blender learning process.

BLENDER

Three.js - a JavaScript library that simplifies the creation and rendering of 3D graphics in a web browser

I started learning Three.js mainly to build this portfolio website. It began with getting comfortable in VS Code and learning HTML, CSS, and JavaScript through YouTube tutorials. Once I grasped the basics, I dove into Three.js to showcase my own 3D models interactively on the web.

I explored the official documentation and examples, reverse-engineering many of them to understand how each feature worked. With the help of ChatGPT and Claude AI, I experimented, refined my ideas, and customized the code to fit my design goals.

This whole portfolio is a sample of how I applied what I learned from Three.js. At the bottom, there’s a simple game about surviving and jumping through platforms to avoid the tovic chemicals rising.

THREEJS